Regulatory requirements, a shortage of skilled workers and increasing pressure to act sustainably, are fundamentally transforming food logistics.

Many operators face the same questions: How can processes be made more efficient, packaging waste reduced and food quality ensured?

Our Customer Success Stories show how a wide range of operators – from large-scale kitchens and caterers to public institutions – successfully overcome these challenges with Rieber system solutions. Whether through digital container management, automated reusable systems or centralized production with vacuum technology, all examples have one thing in common: standardization, efficiency and future readiness.

Case 1 – Zieglersche Wilhelmsdorf (Reusable & CHECK TRACE) See more here

- 26,390 GN components in circulation, paperless documentation, error rate <0.3%

- 60% less time spent, approx. 175,000 documentation pages digitized per year

- Around 110 t of single-use plastic avoided annually

Case 2 – Catering Gesellschaft Himmelsthür (CHECK TRACE + JOMOsoft) See more here

- 100% traceability and real-time production data

- 80% reduction in admin/documentation

- 60% time savings in order picking

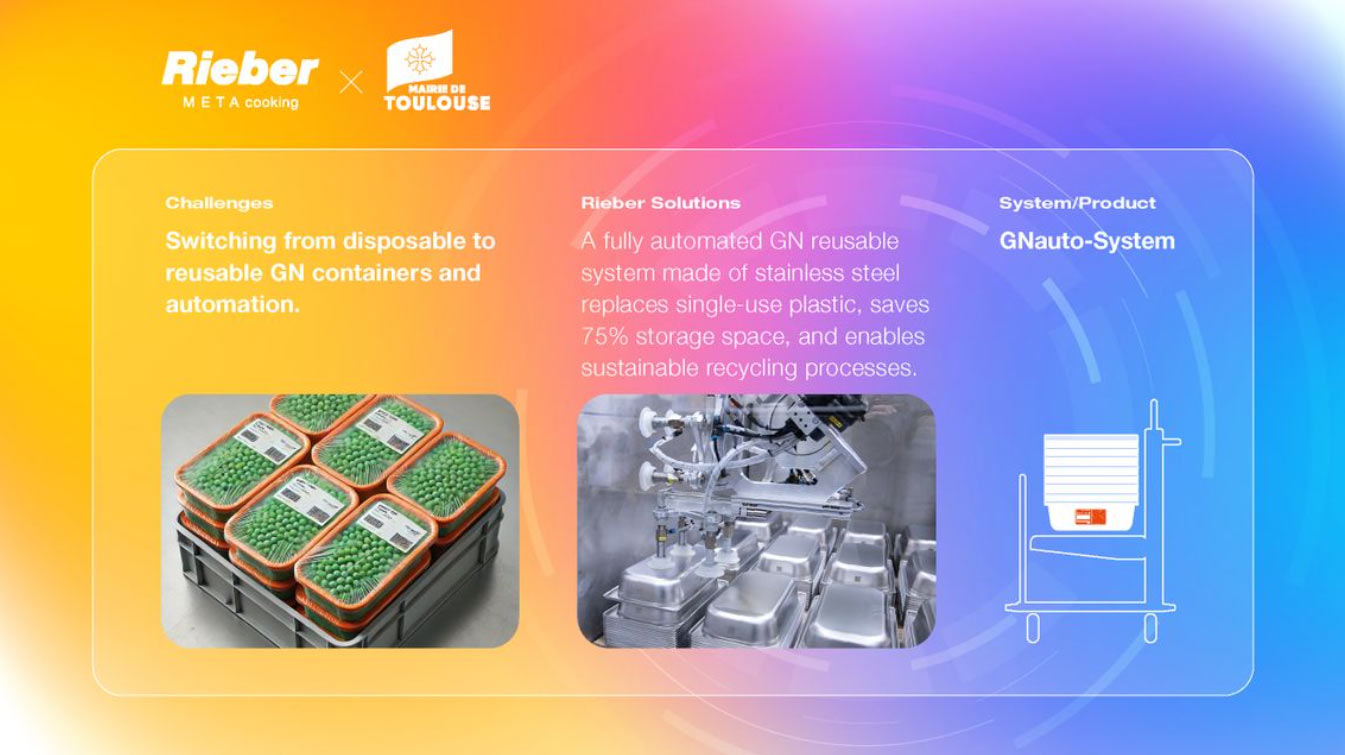

Case 3 – France / EGAlim (Reusable GNauto) See more here

- 500,000 GNauto containers and lids in use

- 75% less storage space; fully automatable thanks to standardized sizing

- 100% compliant and food-safe

Case 4 – BruderhausDiakonie (Centralized Production with vaculid®) See more here

- 15,000 vaculid® GN containers in use

- Consistent quality, standardized and plannable processes

- No packaging waste; energy and labor savings

Conclusion – Standardization & Digitalization

Rieber GN as the foundation: with smart QR codes (GS1 Digital Link), ERP integration and a durable stainless steel reusable system.

Explore more insights and key figures in our new Customer Success Stories brochure.

Zieglersche Wilhelmsdorf x Reusable System & CHECK TRACE

At Die Zieglerschen in Wilhelmsdorf, around 6,500 meals are produced daily for approximately 220 destinations. The high turnover of GN containers long resulted in losses, reorders and extensive manual documentation and order picking.

With CHECK TRACE, the entire reusable process has been fully digitalized.

- 26,390 GN containers and lids in circulation

- 110 t of single-use plastic packaging saved per year

- 60% less time required

- 175,000 documentation pages per year

- Error rate below 0.3%

- Paperless documentation

All reusable items are equipped with QR codes and are seamlessly tracked via CHECK TRACE – directly linked to the Sanalogic ERP system. The result: maximum transparency, lower costs and no more container losses.

Catering Gesellschaft Himmelsthür x CHECK TRACE + JOMOsoft

The Catering Gesellschaft Himmelsthür supplies over 11,000 meals daily to nursing homes, schools and daycare centers. Complex meal plans, individual portioning and high logistical demands made day-to-day operations time-consuming.

By combining CHECK TRACE with an interface to JOMOsoft, the entire production and order-picking logistics process was digitalized.

- 100% digital traceability of all GN containers

- Real-time production data

- 80% reduction in administrative and documentation effort

- 60% time savings in order picking

The result is an efficient and transparent production workflow where every meal, every container and every process step is digitally captured and controlled.

Mairie de Toulouse x Reusable GNauto

Since January 2025, the French EGAlim law has prohibited the use of single-use plastics in the food logistics of public institutions. This new regulation poses major challenges for canteens, schools, hospitals and universities: millions of meals must be handled daily in a legally compliant, hygienically safe and logistically efficient way.

To meet these requirements, a new GN container was developed specifically for this purpose – GNauto. A stackable, robot-compatible stainless steel reusable system with an integrated QR code that optimizes storage space, automates processes and enables full traceability.

Today, 500,000 GNauto containers and lids are already in use across France – setting a new standard for sustainable, efficient and compliant food service operations.

- 75% less storage space

- Automation through standardized sizing

- 100% legally compliant & food-safe

The system enables space-saving storage, automated processes and seamless traceability – a new standard for large-scale catering.

BruderhausDiakonie x centralized production with vaculid®

The BruderhausDiakonie supplies around 3,500 people every day across more than 200 facilities. In the past, meals were prepared decentrally – involving significant effort, packaging waste and inconsistent quality.

With the shift to a centralized production system using vaculid®, meals are now produced under vacuum, transported and regenerated on site – without the need for exhaust systems or high-voltage power connections.

- 15,000 vaculid® GN containers in use

- Consistent food quality

- Plannable, standardized processes

- No packaging waste

- Energy and labor savings

Durable stainless steel containers form the backbone of this system – many have been in use for decades and are still fully functional.

All success stories have one thing in common: the consistent use of standards.

- GN sizing as a universal foundation

- QR codes with GS1 Digital Link for real-time information

- Compatibility with existing ERP systems

- Durable stainless steel containers as sustainable infrastructure

Whether analog optimized or fully digitally integrated – Rieber systems deliver measurable efficiency, resource savings and transparency throughout the entire value chain.