How can induction cooking help businesses run more efficiently and more sustainably

How can induction cooking help businesses run more efficiently and more sustainably

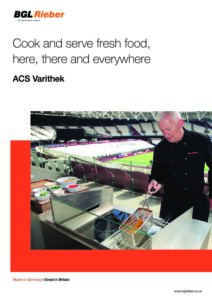

Rieber Varithek induction is mobile! It comes in wok format and as flat hobs 1/1 GN. It helps efficiency and sustainability in several ways. As a fixed cooking station, Rieber induction has the option of self-ventilation, which removes the need for overhead ventilation. As a mobile cooking station, the Rieber Varithek induction modules work within a mobile front cooking station which has the option of self-ventilation and fire suppression. This makes Rieber Mobile Induction ideal for catering anywhere, for events and demonstrations, or as a temporary kitchen during refurbishment.

Mobile equipment improves sustainability because it provides multiple forms of cooking, in a hygienic modern format. Varithek hobs include wok, flat hobs, pasta cooker, fryer, griddle, and also hot holding. These can be used independently, for example, within a fixed servery counter under overhead ventilation, for lunch service.

What differences does induction make in a professional kitchen?

With the current energy crisis, induction is an outstanding winner over gas in terms of cost in use.

The efficiency differential between gas and induction always meant induction proved more economic in the long term and this has now been accelerated by recent price increases.

With operators looking to cut bills long term, demand has never been stronger in the UK.

Once chefs feel the power from a quality induction hob, there is no turning back.

Quality of manufacture and reliability are key buying criteria, and the choice of cooking modules from the German-made Varithek provides the flexibility needed for almost any menu.

The two or three module Varithek ACS Front Cooking Induction Stations are simple to use and ideal to standardise on for staff training.

How can induction help operators achieve net zero carbon emission goals?

Varithek manufacturer Rieber invented ‘standardised system solutions’ to help caterers achieve net zero by minimising the amount of energy, water and chemicals used in cooking, storing, transporting, and serving food.

Varithek Induction Hobs and the ACS Front Cooking Station minimise energy use and are just one part of the cooking process. They are manufactured in GN format which means that every inch of the cooking surface is used for cooking, so no heat or power is wasted.

The use of standardised GN containers – and GN sized fridges and freezers – means no space is wasted for storage, minimising energy use per portion stored.

Using the same GN container for cooking, storage, transportation and serving improves efficiency, cuts storage space, handling and labour and cuts dishwashing, a major user of energy, water, and chemicals in the kitchen.

To achieve net zero carbon emission goals, Rieber has digitised its GN containers. Using the digital platform CHECK CLOUD, information such as storage and cooking temperatures, food type, volume, date, time, what GN container/s are used to store the food and the food transport boxes used to move the food, are holistically networked, and organised. CHECK CLOUD can also be used for tracking the customer and facilitating cashless sales.

Most importantly though, CHECK CLOUD ensures HACCP can be followed throughout the cooking process, always providing safety.

Rieber called this innovation ‘META cooking’!

“We connect people, food, and our kitchen systems, to automatically provide the operator with the right information, so that food quality and HACCP safety can be reproduced easily and everywhere and can be guaranteed at any time.

“The future for sustainable catering is mobile, energy-saving, transparent, digitally organised and traceable using standardised GN reusable food containers made of durable and food-safe stainless steel.”